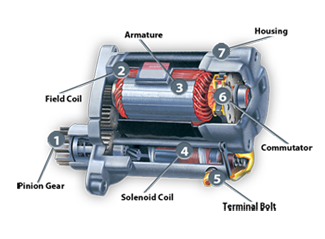

Remanufactured Starter Motor Assemblies & Components

• Are designed and tested to meet specifications for durability and reliability under extreme conditions.

• Use critical replacement parts that are 100% new OE components

• Benefit from the same innovations and upgrades that are applied to current OE products to help ensure performance, safety, and reliability.

Why a Starter Motor or Starter Drive May Fail

• Are designed and tested to meet specifications for durability and reliability under extreme conditions.

• Use critical replacement parts that are 100% new OE components

• Benefit from the same innovations and upgrades that are applied to current OE products to help ensure performance, safety, and reliability.

Related Components to Check

• Electrical connections throughout the starter circuit (battery, ignition switch, etc)

• Starter engagement to the engine flywheel

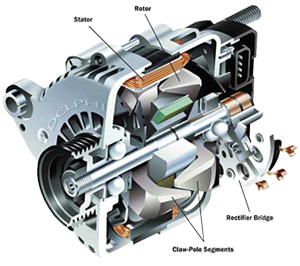

New & Remanufactured Alternators

• Are produced and tested to specifications. Testing is conducted for current output, cut-in speed and high-temperature durability.

• Critical replacement parts such as brushes and bearings that are 100% new OE components to ensure product performance, superiority, safety and reliability.

• Benefit from the same innovations and upgrades that are applied to current OE products to help ensure performance, safety and reliability.

• Use only voltage regulators that are application-specific to a vehicle's system-charging architecture - maximizing battery life.

Why an Alternator May Fail

• Extreme use or from exposure to extreme environmental conditions.

• An alternator may not function properly due to malfunctioning electrical connections, or because it is being driven properly by the engine accessories belt.

Contact

Hours

- Mon-Fri 8am-4:30pm